Если вас беспокоит навоз с высокой влажностью — медленное брожение, высокое энергопотребление, растущие транспортные расходы, низкая эффективность производственной линии — то ваша проблема, скорее всего, не технологическая, а связана с критически важным оборудованием для предварительной обработки.

Сегодня мы не будем говорить об общих концепциях, а сосредоточимся на ключевом продукте, который может напрямую снизить ваши затраты, повысить эффективность и улучшить качество: интеллектуальном и эффективном обезвоживателе навоза. Это не просто «удаление воды», это отправная точка для раскрытия потенциала вашего производства органических удобрений.

Почему «обезвоживание» — это «первый критический этап» на вашей производственной линии?

Необезвоженный животный навоз (особенно свежий свиной, куриный помет и т.д.) часто имеет влажность 70-80%. Его прямое попадание в стадию брожения приводит к:

– Длительному циклу брожения: перенасыщение влагой, плохая аэрация, подавление активности аэробных микроорганизмов.

– Серьезным энергозатратам: затраты на переворачивание и аэрацию возрастают в разы.

– Нестабильному качеству продукции: трудно достичь стандартной грануляции, низкая концентрация питательных веществ.

– Высоким экологическим рискам: вероятность образования фильтрата и вторичного загрязнения.

Вывод: Эффективное обезвоживание — это абсолютное условие для достижения контролируемого, эффективного и экономичного производства компоста уже на начальном этапе.

Мы представляем не просто машину, а комплексное решение для обезвоживания

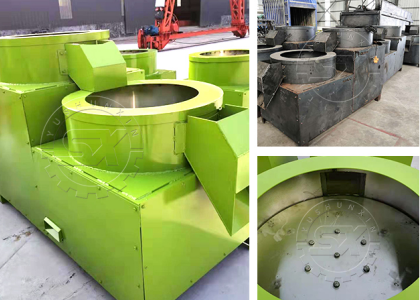

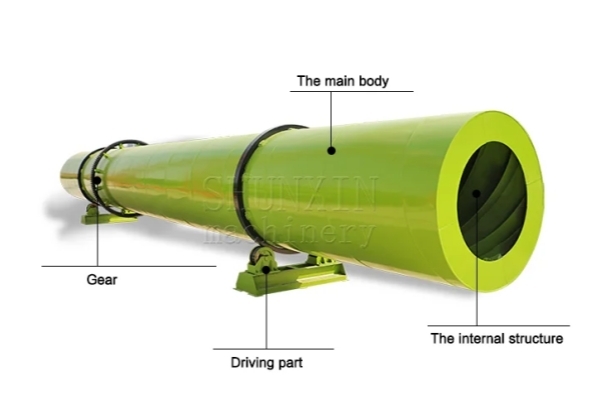

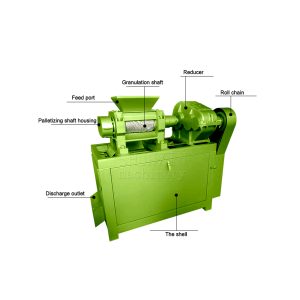

Наша 【Серия интеллектуальных спиральных пресс-обезвоживателей】 разработана специально для крупномасштабного производства органических удобрений и утилизации навоза на крупных животноводческих фермах, превращая проблему в преимущество.

Ключевые преимущества, решающие основные проблемы:

1. Исключительная эффективность обезвоживания

– Большая производительность: Одна машина может обрабатывать 10-30 кубометров исходной навозной жижи в час, обеспечивая непрерывное производство.

– Высокий коэффициент извлечения сухого вещества: Благодаря оптимизированной конструкции шнека и регулировке давления сита, влажность навоза может быть снижена с более 80% до идеального для брожения диапазона 55%-65% за один проход.

– Более тщательное разделение: Твердая фракция представляет собой рыхлые комки, удобные для последующего дробления и смешивания; жидкая фракция прозрачная, что значительно снижает нагрузку на последующую очистку воды.

2. Прочная и долговечная конструкция, созданная с мастерством

– Усиленные ключевые компоненты: Использование шнека из износостойкого сплава и сита из высокопрочной нержавеющей стали увеличивает срок службы в разы, противостоя коррозии и истиранию.

– Мощная и стабильная силовая установка: Укомплектована стандартными тяжелыми электродвигателями и редукторами, обеспечивающими стабильную работу в условиях высокого перепада давления и больших нагрузок.

– Автоматическое управление: Возможна комплектация интеллектуальной системой управления на базе ПЛК для запуска/остановки одной кнопкой, мониторинга состояния и сигнализации об ошибках, снижая зависимость от оператора.

3. Значительная экономическая и экологическая выгода

– Немедленная экономия затрат: Уменьшение объема материала после обезвоживания на 30%-40% напрямую снижает энергозатраты на переворачивание компоста, транспортные расходы и расход добавок.

– Скачок в эффективности: Обеспечение стадии брожения «качественным сырьем» сокращает общий цикл ферментации более чем на 20%, значительно увеличивая пропускную способность линии.

– Соответствие экологическим нормам: Сокращение объема в источнике, эффективный контроль фильтрата, помощь в легком прохождении экологической экспертизы проекта.

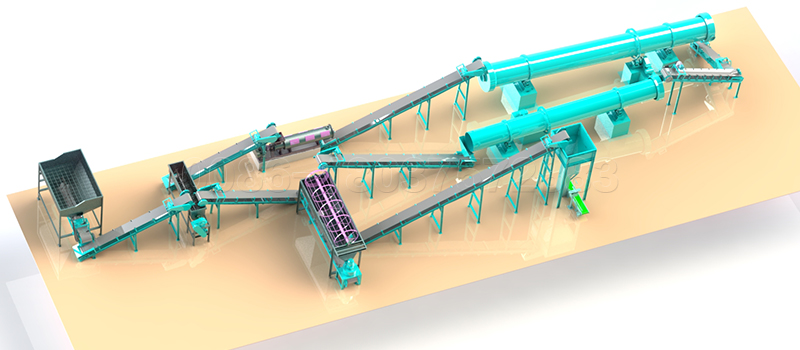

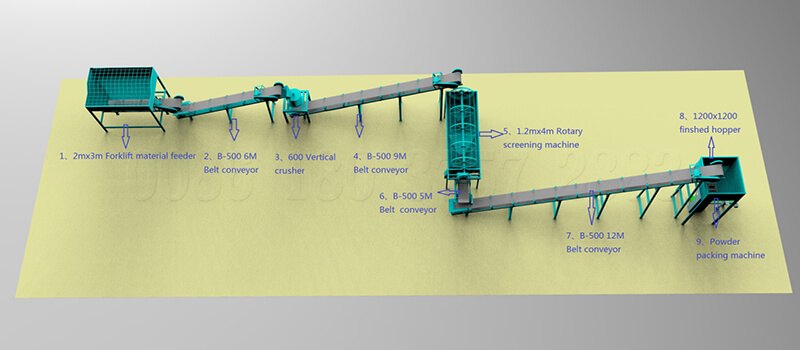

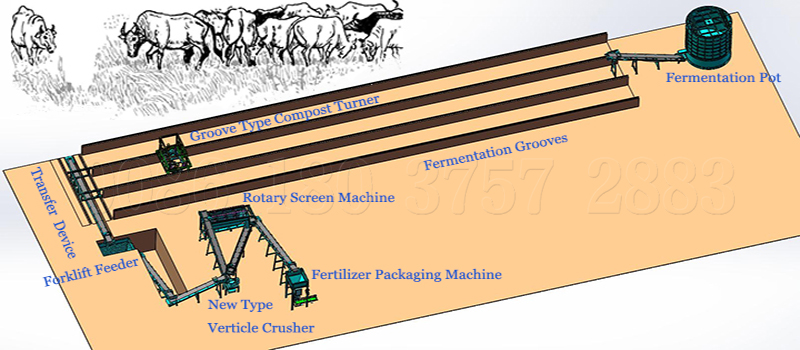

Широкий спектр применения для различных технологических маршрутов

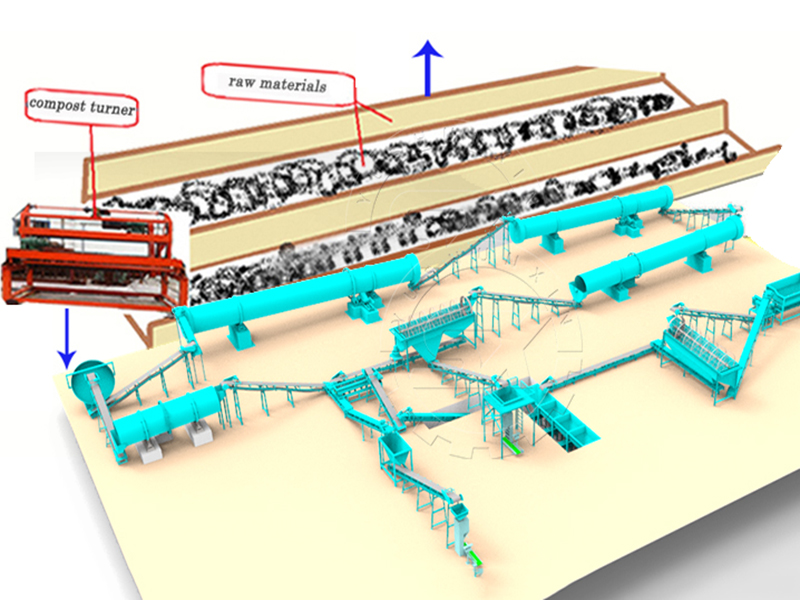

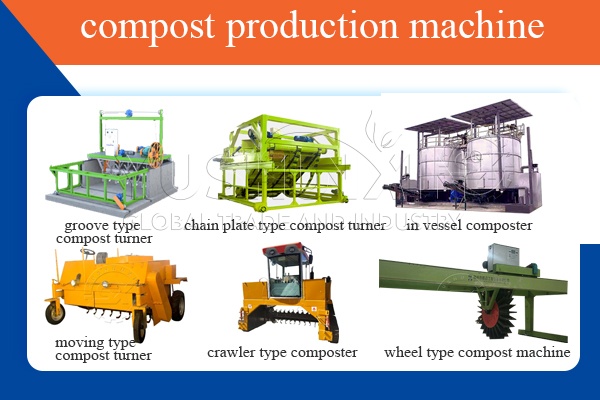

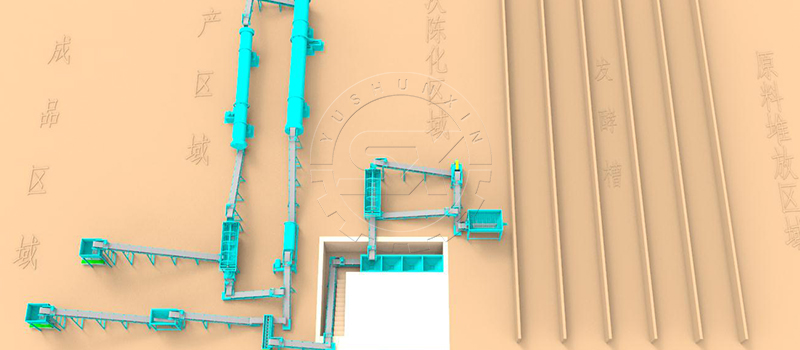

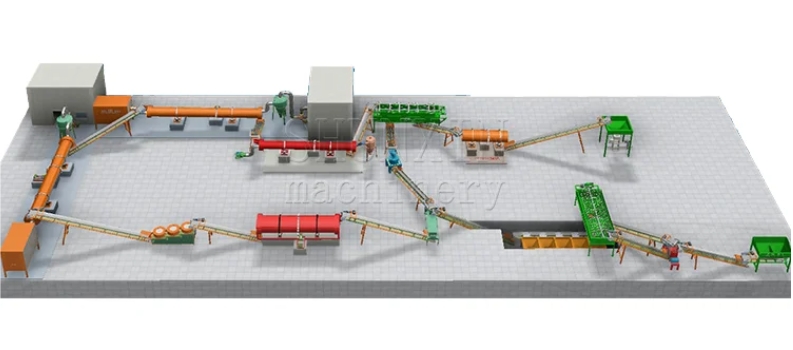

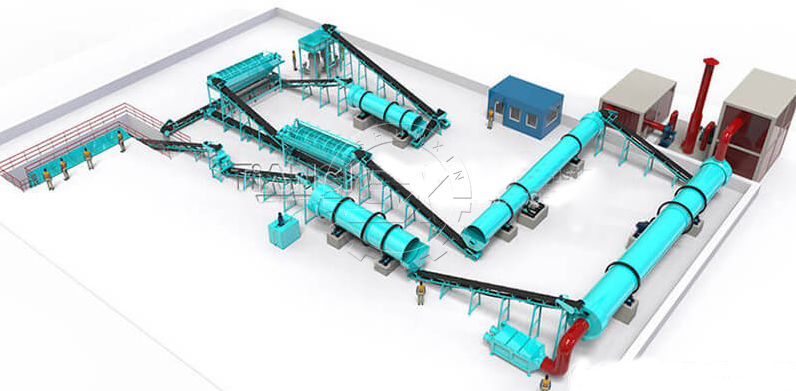

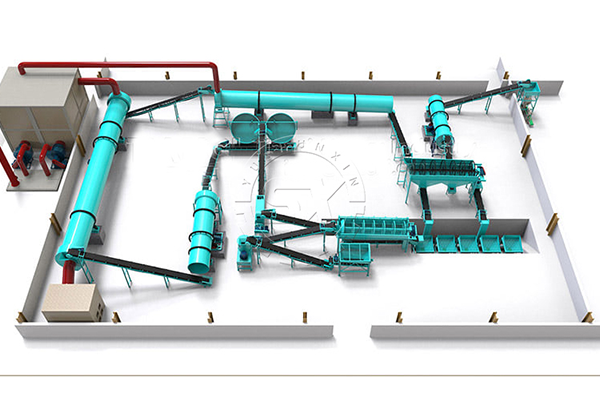

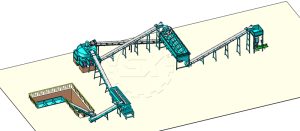

Независимо от вашей последующей технологии — буртовое, валковое или закрытое реакторное брожение — качественная предварительная обработка обезвоживанием является общей необходимостью. Данное оборудование особенно подходит для:

– Ежедневной обработки навоза на крупных свинофермах и птицефабриках.

– Проектов по утилизации навоза с окрестных ферм, реализуемых заводами по производству органических удобрений.

– Центров переработки навоза, построенных инжиниринговыми экологическими компаниями.

– Проектов, требующих обезвоживания и уменьшения объема пищевых отходов, сброженного осадка и т.д.

Выбирая нас, вы получаете не просто оборудование:

Мы понимаем, что покупка тяжелого оборудования — это важные инвестиции. Поэтому мы предлагаем поддержку на протяжении всего жизненного цикла:

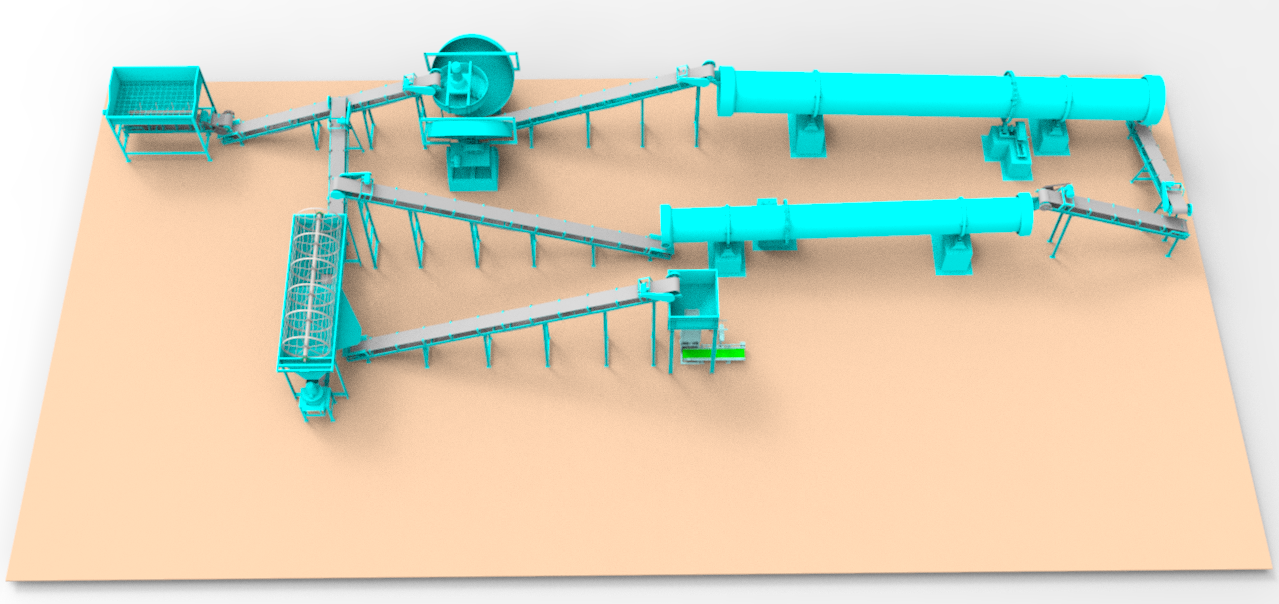

– Бесплатное проектирование решения: Персональные рекомендации по выбору модели и планировке производственной линии на основе характеристик вашего сырья, объема переработки и технологических целей.

– Поддержка при монтаже и вводе в эксплуатацию: Выезд инженеров для обеспечения скорейшего вывода оборудования на оптимальный режим работы.

– Обучение операторов: Комплексное обучение вашей команды для обеспечения безопасного и эффективного производства.

– Надежное послепродажное обслуживание: Механизмы оперативного реагирования, наличие необходимых запасных частей для максимального обеспечения непрерывности вашего производства.

Действуйте немедленно! Превращайте «навоз» в ценность, лидируя с самого первого шага!

Навоз с высокой влажностью не должен быть вашей обузой, это неиспользованный ресурс. Инвестиции в правильный обезвоживатель — это установка мощного «сердца» для всего вашего проекта по производству органических удобрений.

Свяжитесь с нами прямо сейчас, чтобы получить:

1. Индивидуальное предложение по оборудованию и расчет стоимости

2. Примеры успешных проектов для аналогичных клиентов

3. Бесплатную услугу пробного обезвоживания вашего сырья (Увидите результат своими глазами!)

Позвольте нам помочь вам зафиксировать прибыль уже на начальном этапе и сделать производство бесперебойным и эффективным! Для получения более подробной информации, пожалуйста, посетите:https://www.sxmashina.com/tverdo-zhidkostnyy-separator/

The demand for these systems has increased, primarily because of the need for more fertilizer for the ever-growing farming industry. Therefore, some research must be done to find these businesses, some of which will give you an exceptional offer on one of their best Windrow composting systems. Go to

The demand for these systems has increased, primarily because of the need for more fertilizer for the ever-growing farming industry. Therefore, some research must be done to find these businesses, some of which will give you an exceptional offer on one of their best Windrow composting systems. Go to